The smart Trick of Welding Inspection That Nobody is Talking About

Table of ContentsCertified Weld Inspector - An OverviewGetting The Certified Welding Inspector To WorkSome Known Details About Weld Inspection The Buzz on Asme InspectorThe 7-Second Trick For Asme Inspection

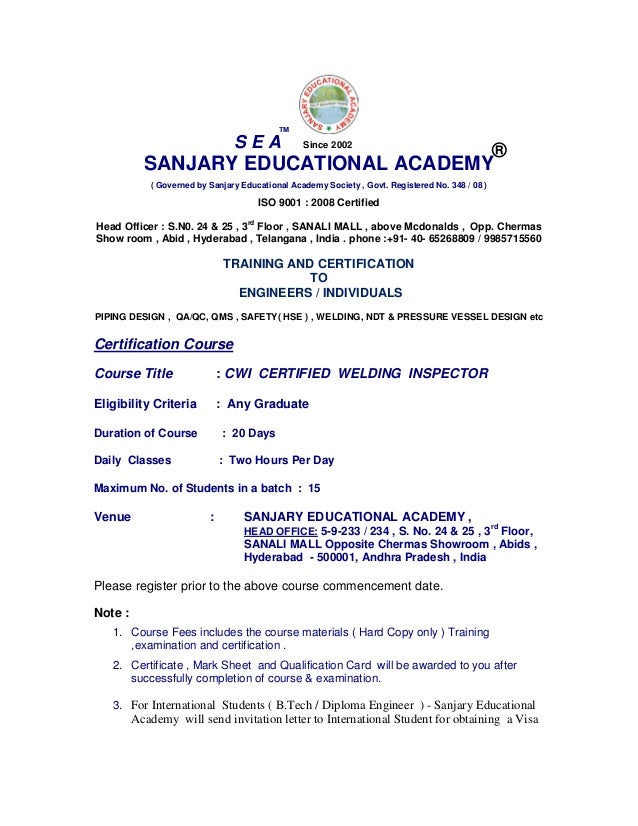

Steel frameworks, such as steel fencings as well as pipelines, are created through a welding process. A Certified Welding Assessor, or CWI, makes sure that these frameworks are welded effectively. The CWI checks the framework for issues, makes use of customized tension equipment to test for toughness, and also executes re-inspections.An AWS Certified Welding Examiner, or CWI, is liable for inspecting weld top quality, workmanship, as well as uniformity to specs. Since welding is an essential element of building construction, automobile production, facilities, and also a lot more, CWIs help guarantee the security of the public - How to become a certified welding inspector. Welding is a vital part of numerous various other industries too, consisting of aerospace, electronics, mining, oil and also gas, as well as shipbuilding.

What Does a Welding Inspector Do? Great welding examiners are included in all stages of welding: from certifying welders as well as procedures to assessing specifications to examination of the final weld.

Certified Weld Inspector Things To Know Before You Buy

These papers include Welding Procedure Specs (WPS), welder qualifications, examination records, job specs, as well as applicable welding codes. An excellent CWI recognizes as well as understands the specs and also code. He or she makes sure that the WPS and welder credentials adapt to those needs. Prior to welding, CWIs check both base steels and filler metals, noting that they follow the WPS and task specifications.

After a weld is finished, a CWI will certainly evaluate it carefully, checking as well as measuring any type of stoppages such as porosity, undercut, splits, insufficient blend, or poor profile. The size of the weld is also determined for correspondence to the task specs - AWS CWI Certification. If any one of the suspensions do not adhere to task needs, they are considered problems and also have to be fixed.

7 Simple Techniques For Asme Inspector

How Does a Welding Examiner Inspect Welds? Welding inspectors use a number of gauging tools to examine weld quality. They utilize tools like rulers, amplifying glasses, flashlights, and also countless assesses to determine dimension, undercut, reinforcement, and various other interruptions of a weld to make sure they are within the appropriate array.

Test takers should score 72% or even more on all three components to gain the CWI accreditation. Additionally, AWS calls for an eye test and a mix of education and learning as well as job experience. For even more comprehensive information about becoming a CWI, most likely to our page concerning the process. How Much Does a CWI Make review in a Year? According to Pay, Scale, an average welder can expect to make $30,000 to $40,000 a year.

Welders have the ability to boost their earning prospective by finding out the assessment profession and also becoming a CWI.That said, it is not uncommon for experienced welders to earn greater than freshly accredited CWIs. Everything relies on the job and the skill required. When it comes to maximizing your wages, it does not injured to get licensed in welding examination.

The Definitive Guide to Welding Inspection

CWIs have good job chances and also high pay since they must be experienced regarding every component of the welding process in order to examine weld quality and take obligation for each project. An efficient CWI is also a reliable communicator.

CWIs should be able to give feedback to welders so they can fix their welds when needed. CWIs have to have thick skin as well as the capacity to speak openly with stakeholders, even when they have to interact something they don't intend to listen to. If a CWI lies concerning issues due to the fact that she or he intends to please the company, the safety and security of the public is placed at stake.

Welding examiners provide quality control by keeping track of the whole welding process. They utilize a variety of devices to check welds. They are evaluated for certification by AWS to make sure ability and knowledge and also they are awarded with higher salaries for their job. Structural Steel Inspector. If you would certainly like to learn more regarding welding evaluation, review our posts on crucial subjects regarding the industry including the CWI test and just how to become a CWI.

About Asme Inspection

Welding Examiners utilize their considerable expertise of welding processes, examination methods, interruptions, materials, qualifications, as well as standards to ensure that weldments as well as welding-related activities abide by all appropriate high quality as well as security requirements. The role of the Welding Inspector is vital to the safety and security as well as architectural strength of the large variety of buildings, vehicles, machinery, and customer items that require solid, safe and secure welds.

Many people believing about spending the time as well as cash required to come to be a CWI, aren't completely educated about what a CWI in fact does. ASME Inspection. CWI Jackie Morris demonstrates just how to make use of a dial caliper to determine the thickness of the product. "A lot of people believe a CWI just looks at a finished weld," claimed veteran Welding Inspector Jackie Morris, but this is simply not the situation.